Åbo Akademi Astra campus

The stormwater drainage from the versatile roof and courtyard areas of the renovated Astra campus was implemented using Peltitarvike's channel drains and other drainage products.

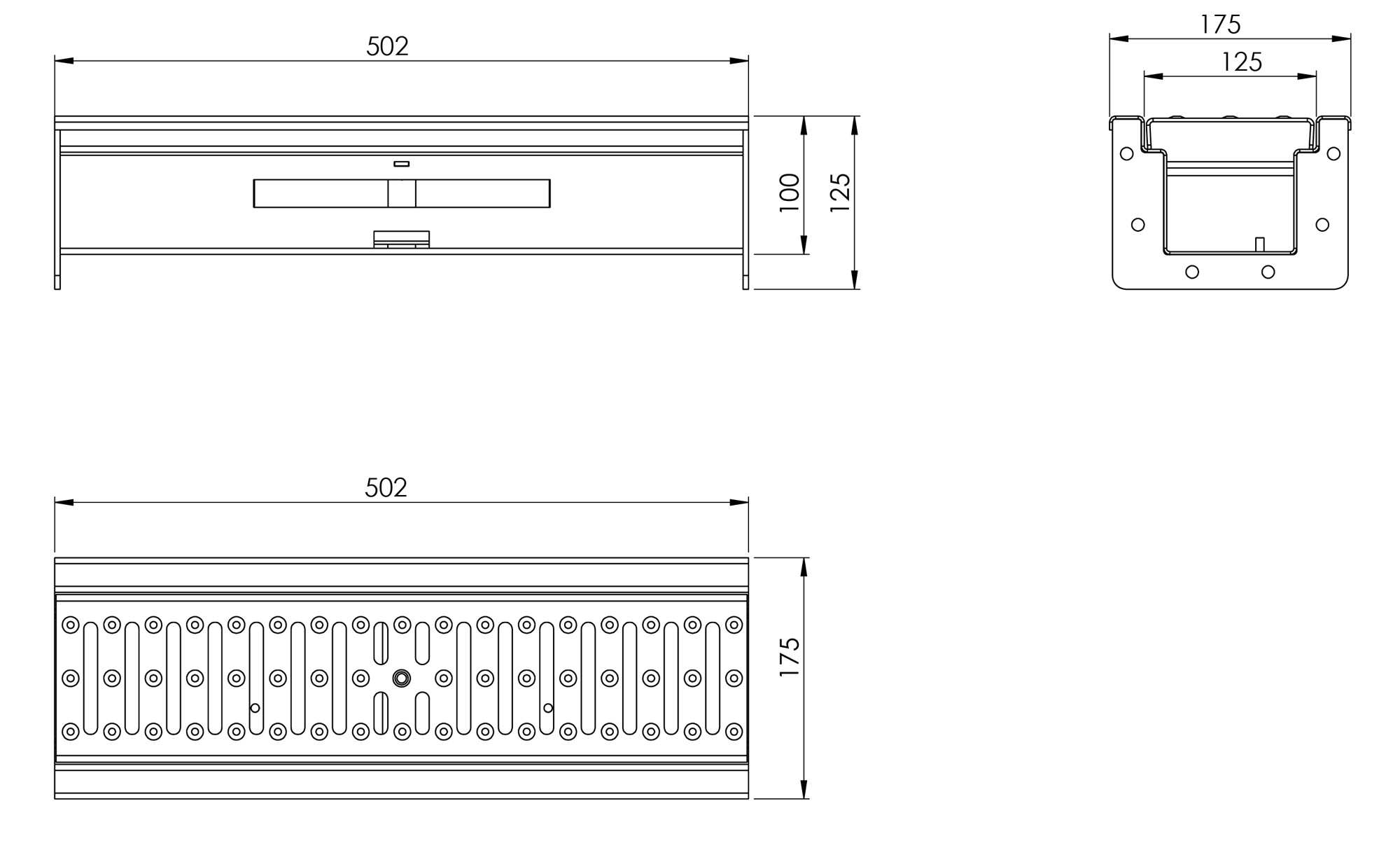

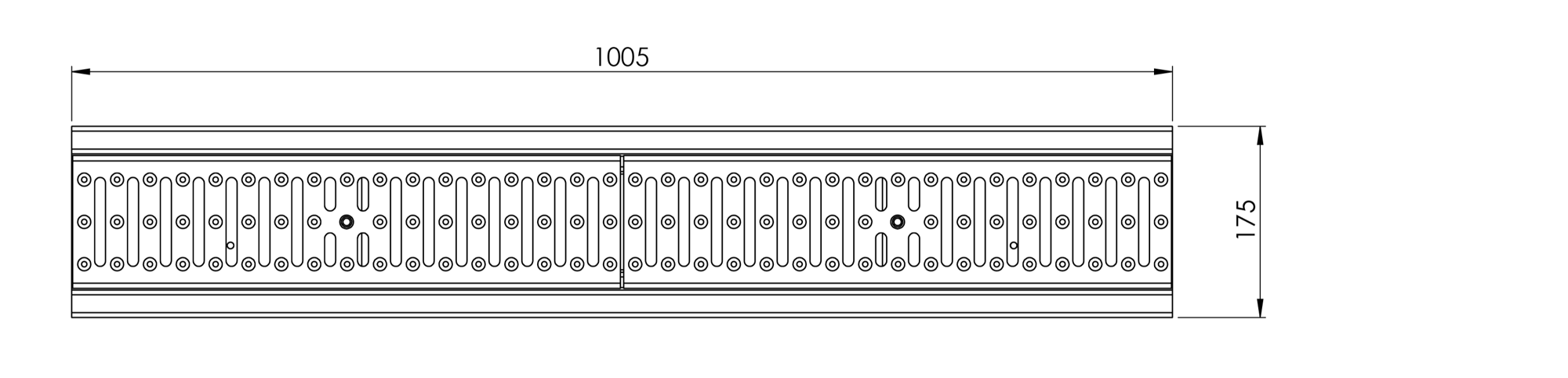

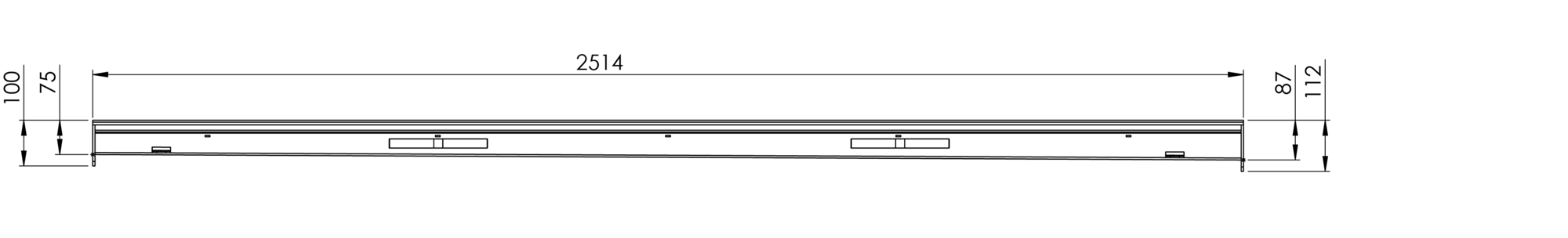

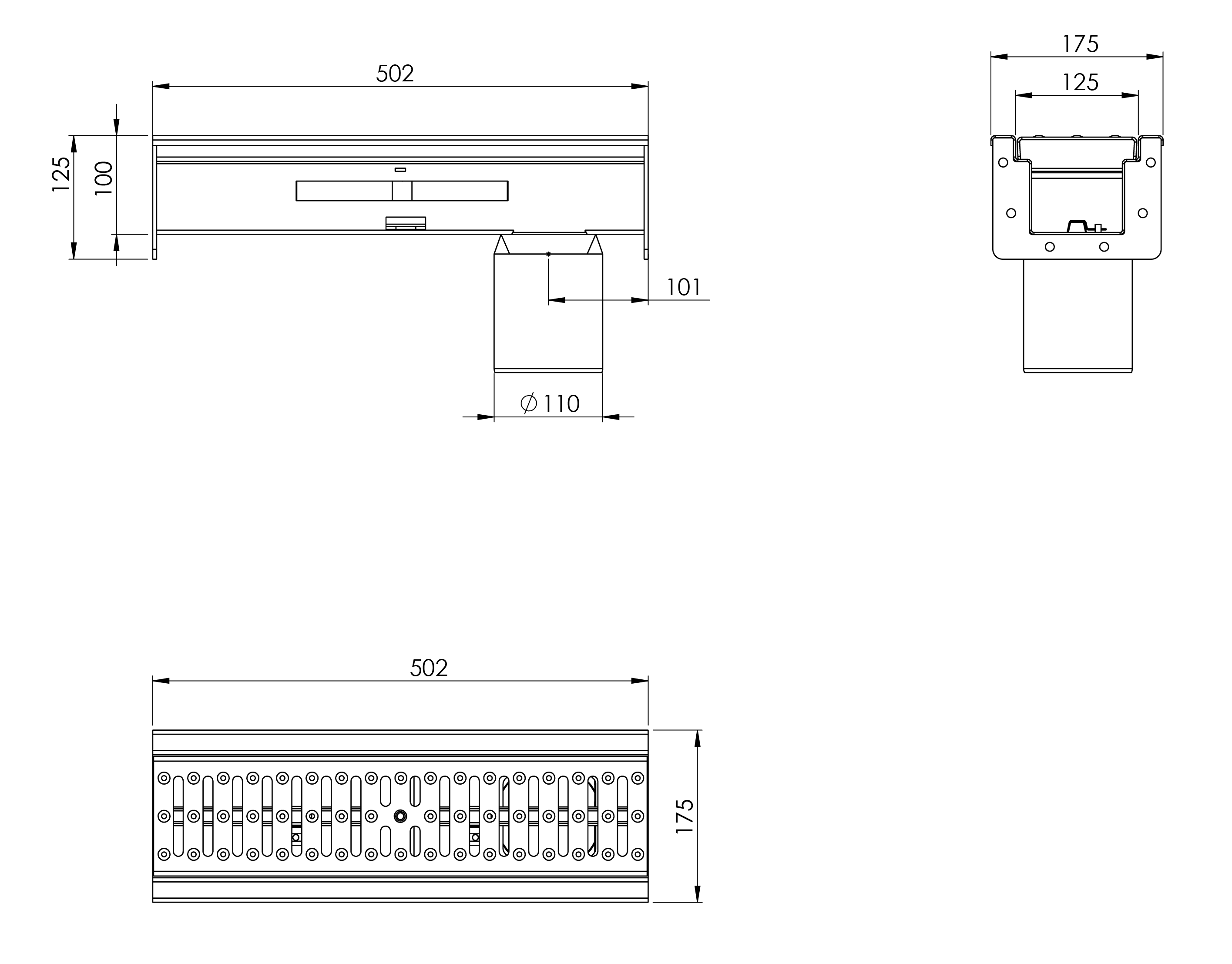

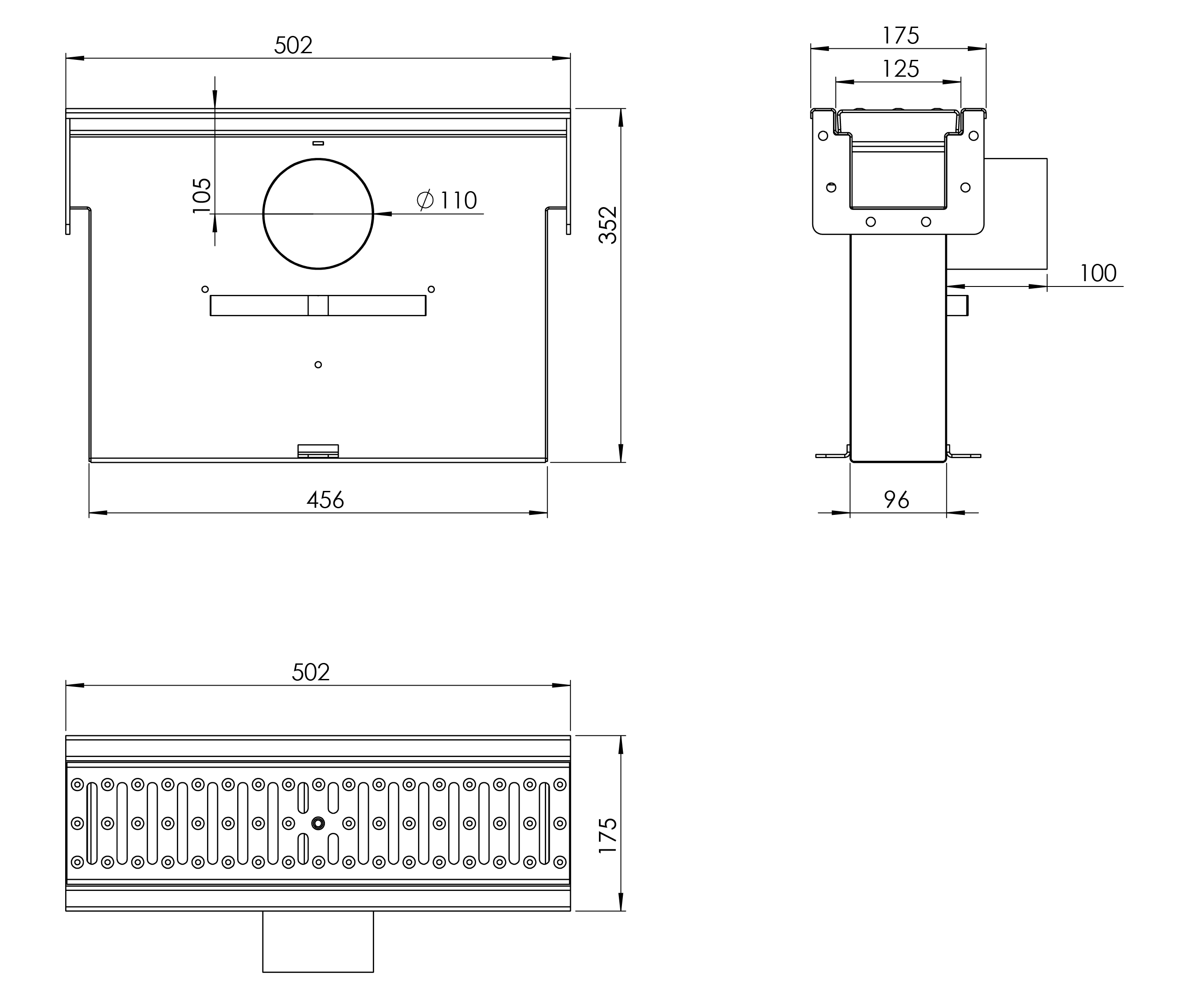

DryLine® Modular is a channel drain made of stainless steel that is an excellent fit for surface water removal from car parks, yard areas, terraces and inverted structures. A channel drainage system made up of standard-sized, easy-to-connect modules provides a functional solution for every application, with quick delivery. The modules and end plates are locked together with bolts and fitted with sealing flanges (EPDM or NBR) - allowing you to build a leak-tight system you can rely on.

The necessary fasteners are supplied with the modules. In addition, the modules are equipped with cast-in supports and mounting feet that allow for easy positioning at the correct height. The channel drain can also be equipped with a self-adjusting thermocable. The thermocable is installed inside a protective case that protects it against mechanical stress. The connection cable is brought into the channel through a watertight pressure grommet.

The DryLine® Modular channel drain meets the requirements of the EN1433 standard.

| Module | LVI number |

| Modular 500 | 3375206 |

| Modular 1000 | 3375205 |

| Modular 2500 | 3375202 |

| Modular 2500, internal slope 75-87 | 3375200 |

| Modular 2500, internal slope 87-100 | 3375201 |

| Modular 500 outlet | 3375203 |

| Modular 500 sump unit | 3375204 |

| Slotted grating 500, stainless steel | 3381354 |

| Mesh grating 500, stainless steel | 3381352 |

| Slotted grating 500, ductile iron | 3381353 |

The channel drain must be maintained regularly. Failure to maintain will reduce or prevent water flow. Particular attention should be paid to cleaning the channel during the gritting season.

* If included in the channel

The stormwater drainage from the versatile roof and courtyard areas of the renovated Astra campus was implemented using Peltitarvike's channel drains and other drainage products.

You must give consent first to display media.