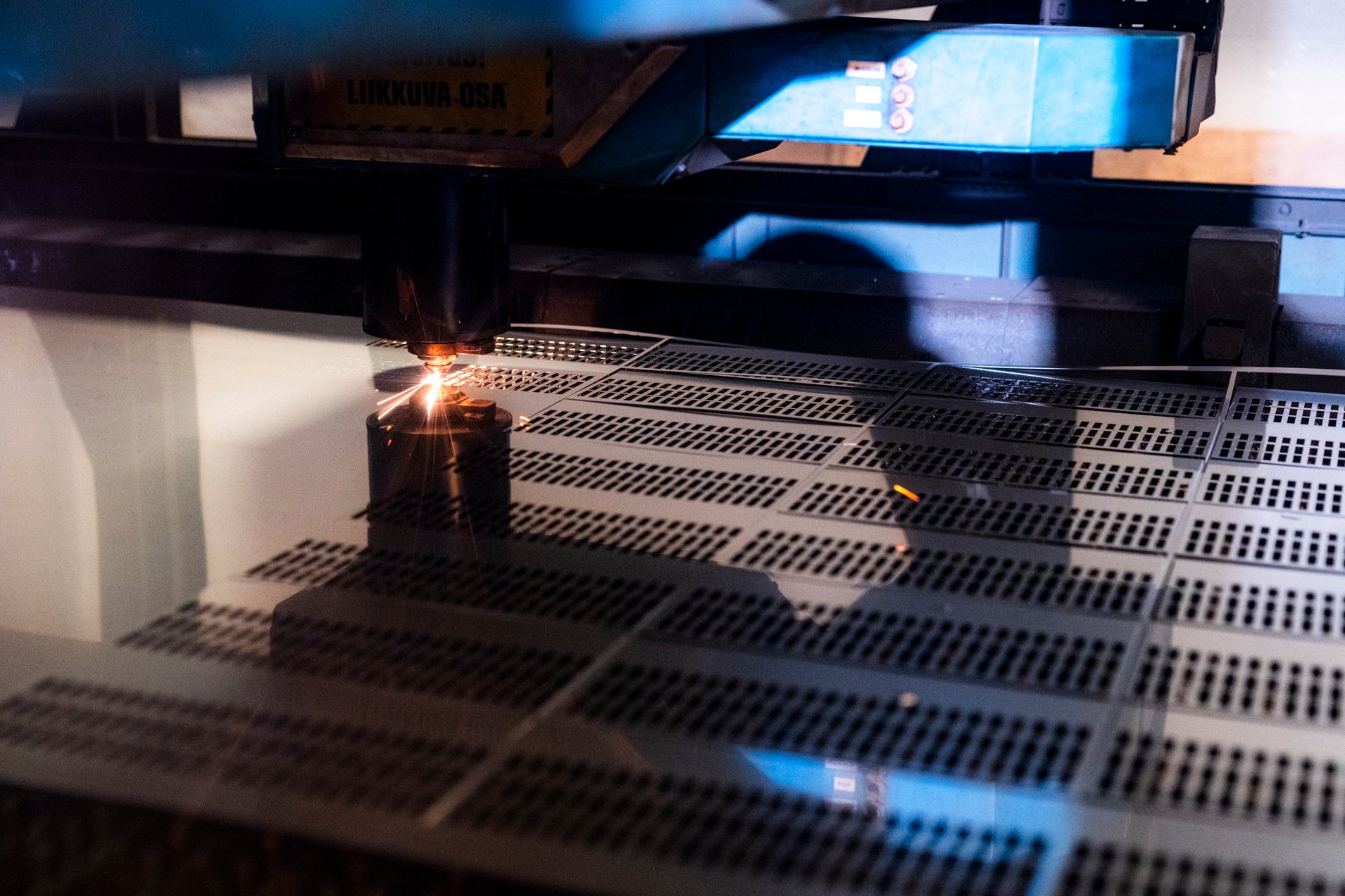

Certified metal laser cutting

Our fibre and CO2 laser cutters allow cutting of metals of different thicknesses, from aluminium to copper and from black iron to stainless steels. We cut both individual prototypes and larger batches, serving a wide range of industries, such as machinery and equipment manufacturers and the construction industry.

Our laser cutting meets the requirements of EN 1090-2, which guarantees the quality of manufacturing up to the EXC4 execution class, enabling deliveries to even the most demanding projects and demonstrating the high level of conformity and quality control of our products.

Laser cutting is versatile for the manufacture of various sheet metal products and is an ideal method for the production of both individual pieces and large batches. Laser cutting of metal enables a very precise cutting mark even in demanding geometries, excellent repeatability and an efficient production process.

Benefits of laser cutting:

-

Accuracy and repeatability: Excellent dimensional accuracy and a clean cutting edge.

-

Versatility: Suitable for various metals and thicknesses.

-

Cost-effectiveness: A fast and accurate cutting process minimises waste and shortens throughput time.

-

Flexibility in design: Enables easy implementation of complex shapes and details.

Our laser cutters

-

Platino Prima Power

2 kW fiber laser, cutting area 3000x1500 mm

- Aluminium/stainless steel max. thickness 5 mm

- Steel max. thickness 15 mm

- Copper/brass max. thickness 5 mm

-

L6 Prima Power

5 kW CO2 laser, cutting area 3000x1500 mm

- Aluminium max. thickness 8 mm

- Acid-resistant steel/stainless steel max. thickness 20 mm

- Steel max. thickness 20 mm